About Us

RODA STAINIESS STEEL LIMITED

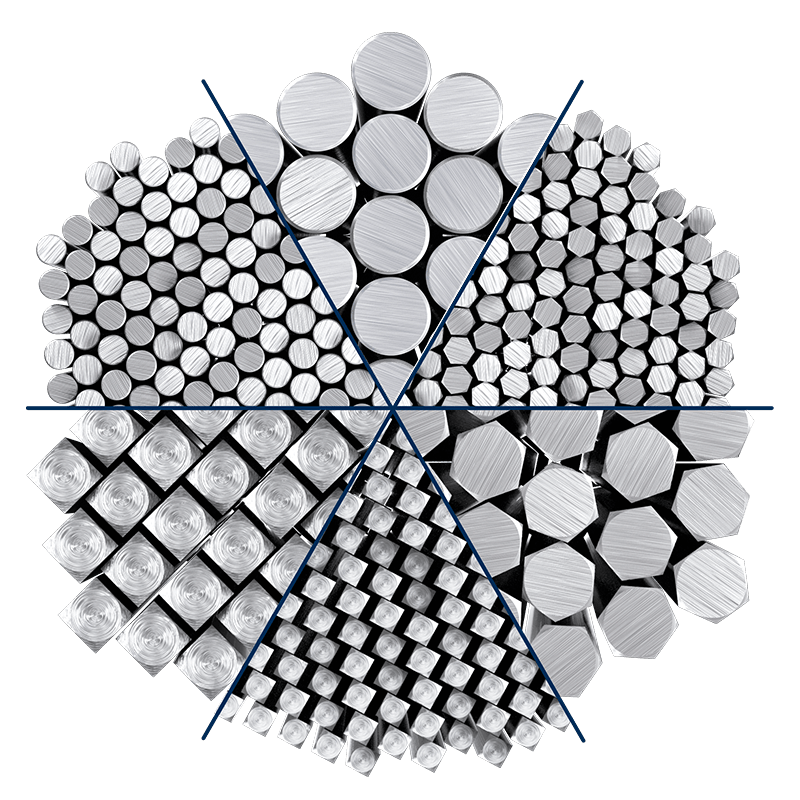

Is a research and development, production, sales as one of the stainless steel manufacturing enterprises, with a number of large storage bases, the company’s stainless steel products inventory of 20,000 tons.

In order to provide customers with high-quality products, the company strictly controls the quality of stainless steel raw materials, over the years, the company has established good cooperative relations with many world-renowned enterprises such as OUTOKUMPU, AVESTA, Japan Metallurgy, Metallurgical Union, Nippon Steel, Kobe Steel and so on.

With a strong technical team and service team, we have accumulated rich experience in the design and production of various stainless steel products to provide customers with effective solutions. Stainless steel products are exported to more than 50 countries and regions in the world, and have been unanimously affirmed by global customers. We are willing to further cooperate with friends all over the world to create a better future.

Expertise, consulting, controls, quality, availability: these are the principles that distinguish the philosophy with which Rodacciai approaches the market, distinguishing itself from competitors on one hand thanks to the quality of the steel produced in its factories, and on the other making an attentive and competent service one of its strengths.

All of the material is carefully controlled also thanks to tests carried out directly in the machine, the systems are of the latest generation and a technical staff with proven experience is available to the customer to recommend the most suitable steel for every need or to study it ad hoc for special uses.

Roda has chosen to represent itself in the first person in the relationship with the final customer: it is equipped with its own structure throughout the world.

This choice has allowed the company to be present, in a widespread way, in the sales areas of its own steels, giving life over the years to a commercial structure that can follow the customer step-by-step, offering a competent consulting service and responding in real-time to every need.

Modernity means equipping oneself with state-of-the-art systems intended to have increasingly better steels. Modernity however is also a special attitude in the approach to work, a production philosophy to be internalized: the steel produced by Roda must be perfect and for this reason, it must be created with the head and heart.

Modernity for Roda therefore also means empowering the people that work in its factories, making sure that each of them is aware that they have a special role in the production process, so that they feel like they are part of the company and always give their best to give the best to the customer.

Modernity is also, last but not least, protecting the environment, the production of clean energy and strict compliance with regulations aimed at not damaging what surrounds us, to deliver a better world than the one that we have inherited to those who will come after us.

The ability to see ahead and to always be able to provide the types of steel most requested by the market requires experience and foresight. The same foresight that in the past, for example, led Roda to the installation of the internal rolling mill and that currently pushes the company to offer a wide range of automatic steels, focusing on stainless steels and growing in the field of alloy steels, in particular those for construction.

Substantial investments give Roda the possibility of producing special steels in the belief that it is necessary to focus on quality, although not closing itself in niche markets and making specialization a key value.

certificates

A leading company in stainless steels

Quality and flexibility have positioned RODA as the leading producer of long products in Spain and one of the leading producers worldwide, with a recognized reputation in major international markets. Our products are currently consumed in the most developed countries of Western Europe (Germany, Italy, Great Britain, France, Sweden, etc.), Asia, and North America.

Professional attention

At every stage of the process, the RODA team monitors the product, from order receipt and review to final product verification and delivery to the customer. This professional approach guarantees our customers a quality product tailored to their needs and on time. This service makes RODA a loyal partner in the supply of stainless steels.

A continuous process control

Throughout the entire process, our control systems ensure optimal product quality. Automated facilities, controlled by professional experts, guarantee continuous monitoring of parameters affecting product quality.

Steel refining in the AOD converter and the solidification process in the horizontal continuous caster are carefully controlled to ensure optimal steel quality. Bar heating during hot rolling and heat treatments are continuously monitored and recorded, ensuring the required mechanical characteristics. A laboratory equipped with the most modern analytical and testing equipment certifies product quality throughout the entire process.